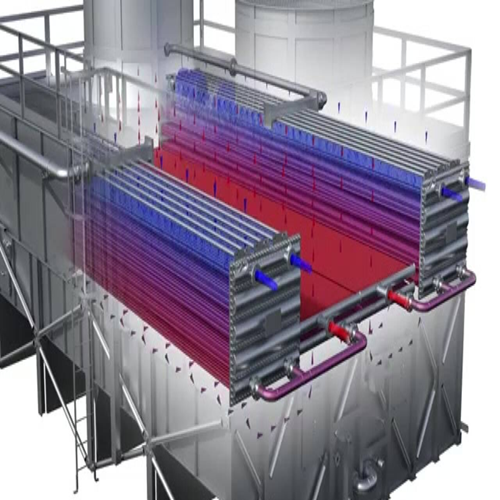

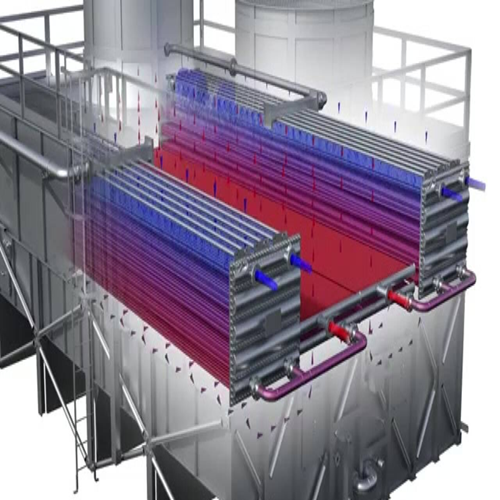

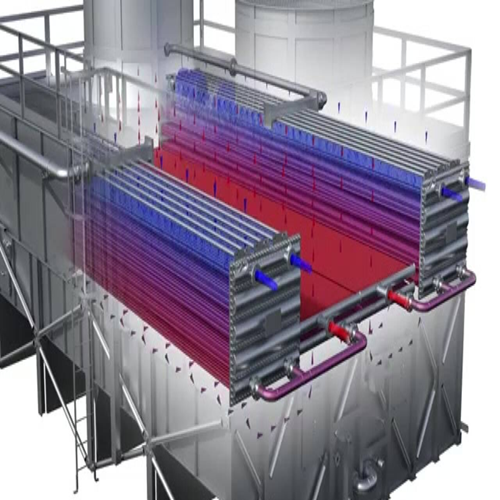

Hybrid Cooling Tower Design (Combination of Air Cooler and Wet Cooling Tower)

Overview: A hybrid cooling tower integrates the benefits of both air-cooled heat exchangers and wet cooling towers into a single system. This design is ideal for environments with water scarcity, high ambient temperatures, or strict plume control requirements—common challenges in petrochemical plants and power generation facilities.

description

Design Methodology:

-

Thermal Load Distribution:

- Split the cooling duty between the dry section (air cooler) and the wet section (cooling tower).

- The dry cooler handles sensible heat removal using ambient air, reducing water usage.

- The wet section polishes the final temperature drop, leveraging evaporative cooling.

-

Configuration Options:

- Series Configuration: Air cooler first, followed by a cooling tower.

- Parallel Configuration: Both units operate simultaneously on separate loops or stages.

- Choose configuration based on climate, cooling range, and process requirements.

-

Materials & Components:

- Use galvanized steel or stainless steel for dry cooler coils.

- Select corrosion-resistant fill and efficient drift eliminators in the wet section.

- Fan systems must be optimized for both air velocity and energy consumption.

-

Control System Integration:

- Implement smart controls to adjust fan speeds and bypass valves based on ambient temperature and cooling demand.

- Automated switching between dry and wet modes can drastically reduce water and power consumption.

-

Water Management:

- Design water circuit with minimal blowdown and make-up needs.

- In some designs, adiabatic cooling (mist pre-cooling for air) is added to further reduce tower water use.

Retrofit & Optimization:

-

Dry Add-on to Existing Tower:

Retrofit an air-cooled coil bank upstream of an existing wet cooling tower to reduce plume and water load. -

Energy Efficiency Improvements:

Add VFDs to fan motors and install real-time control systems for dynamic operation based on process load and climate. -

Plume Abatement:

In cold climates or urban zones, hybrid towers help eliminate visible plume without sacrificing thermal performance. -

Water Savings:

Operate in dry mode during winter or low load periods to significantly cut water consumption. -

Performance Monitoring:

Use IoT sensors for predictive maintenance, water chemistry tracking, and optimization of hybrid mode switching.