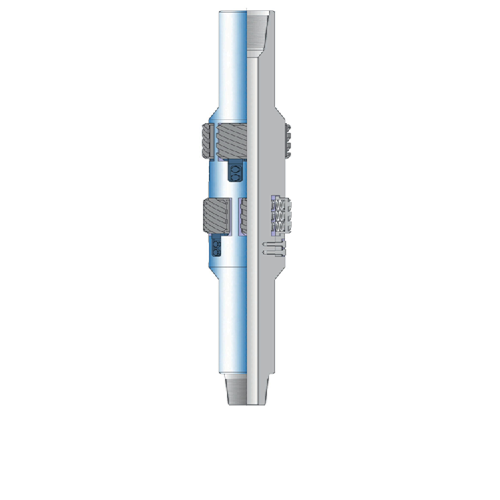

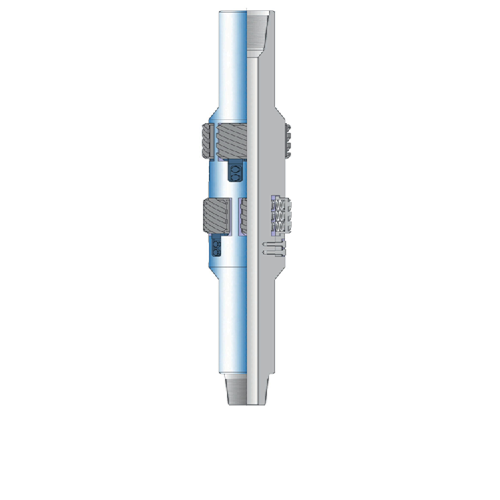

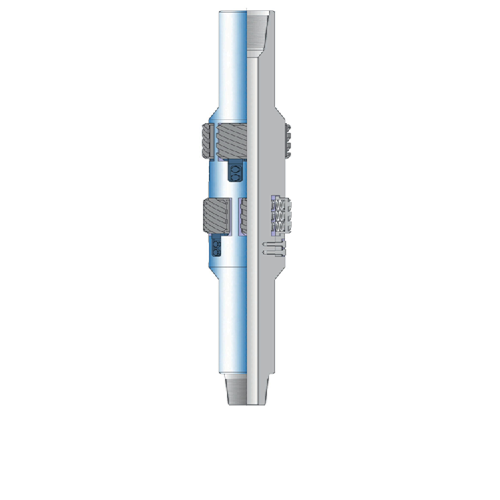

Casing Scraper

The Casing Scraper is used to remove mud or ce- ment sheath, embedded bullets, perforation burrs, rust, mill scale, paraffin, and similar substances from the inside walls of the casing. The importance of keeping this vital “working surface” clean and smooth is readily apparent when it is realized that nearly all subsequent operations in the well are af- fected in one way or another by the condition of casing ID. Standard connections on the Casing Scraper are Reg pin and box. These connections allow installa- tion of the scraper in the drillstring between the drill bit and bit sub. The drill bit is installed below the scraper to serve as a guide and prevent plugging the circulation hole through the scraper. This tool arrangement also allows for both the drillout and sheath removal of any previous cement retainer operations.

description

For maximum scraping efficiency, it has been found desirable to run the scraper completely through the restricted section without rotation, then pull back up and make a rotary run through the section. This cleans most of the scale, bullets, cement, and other extraneous materials off the casing wall. Rotating the tool as the string is lowered causes the scrap- ing surfaces to shear off any remaining burrs or ob- structions missed on the first pass with the scrap- er. The scraper is rerun to check for smoothness (especially if preparing to set a packer) before trip- ping out of the hole. If the weight indicator does not show any irregularities, the casing should be clean.

Features/Benefits

- Carburized scraping edges on the blades

provide endurance and maximum service

- Cleaning can be accomplished by either ro- tation or reciprocation as a result of blade arrangement in the body that gives full 360° contact with the casing ID

- Each blade is cut with left-hand helical grooves to allow the tool to scrape down in- side the casing