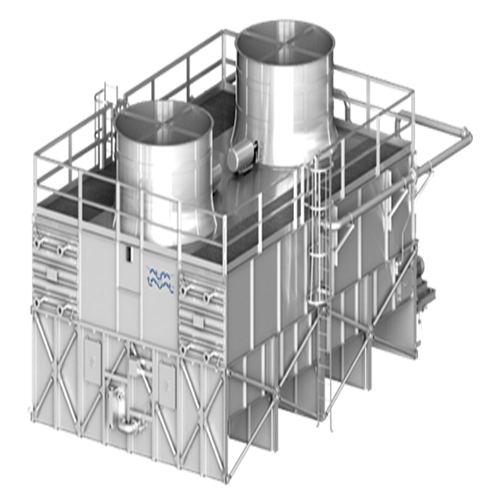

Air Cooler Design for Petrochemical and Industrial Applications

Overview: An air cooler (also known as an air-cooled heat exchanger) is a highly efficient system designed for removing heat from fluids or gases using ambient air. Air coolers are often employed in situations where water availability is limited or where evaporative cooling (such as in cooling towers) is not feasible. These systems are widely used in petrochemical plants, power generation, and oil & gas applications.

related groups :

tags :

description

Design Methodology:

-

Heat Transfer Mechanism:

- Sensible heat is removed from the fluid or gas through heat exchange with ambient air.

- The system typically consists of fin-tube heat exchangers where air flows over the fins, carrying heat away from the fluid within the tubes.

-

Airflow & Fan System:

- Air coolers rely on large axial or centrifugal fans to force air across the heat exchanger surface.

- Proper fan design and placement are crucial to achieving the optimal heat transfer rate and minimizing power consumption.

-

Material Selection:

- Corrosion-resistant materials like aluminum, copper, or stainless steel are used for the heat exchanger tubes and fins to withstand harsh industrial environments.

- Epoxy-coated or galvanized steel can be used for the frame and structure to improve longevity.

-

Compact and Modular Design:

- Air coolers are designed to be space-efficient and modular, which allows for easy integration into existing systems and flexibility in scale.

- Modular units enable easy expansion based on cooling load increases.

-

Customization for Process Requirements:

- Air coolers are customizable for various fluid types (e.g., water, oil, gases) and temperature ranges.

- Adjustments to airflow rate, fan speed, and heat exchanger surface area allow the air cooler to meet specific process needs.

Retrofit & Optimization:

-

Energy Efficiency:

- Variable Frequency Drives (VFDs) can be installed to control fan speed and optimize energy consumption.

- Consider counter-flow designs to maximize efficiency, where the air flows against the fluid in the heat exchanger.

-

Maintenance and Cleaning:

- Use easy-access panels for routine maintenance and cleaning of air cooler fins to ensure consistent performance.

- Self-cleaning filters can be added to prevent clogging by dust and debris.

-

Noise Reduction:

- Acoustic dampeners or low-noise fans can be integrated to reduce noise pollution in areas sensitive to noise levels.

-

Heat Recovery:

- In certain applications, heat recovery units can be added to capture excess heat from the air cooler for reuse in other processes.

-

Performance Monitoring:

- IoT-enabled sensors can be used for real-time monitoring of air cooler performance, ensuring proper operation and predictive maintenance.